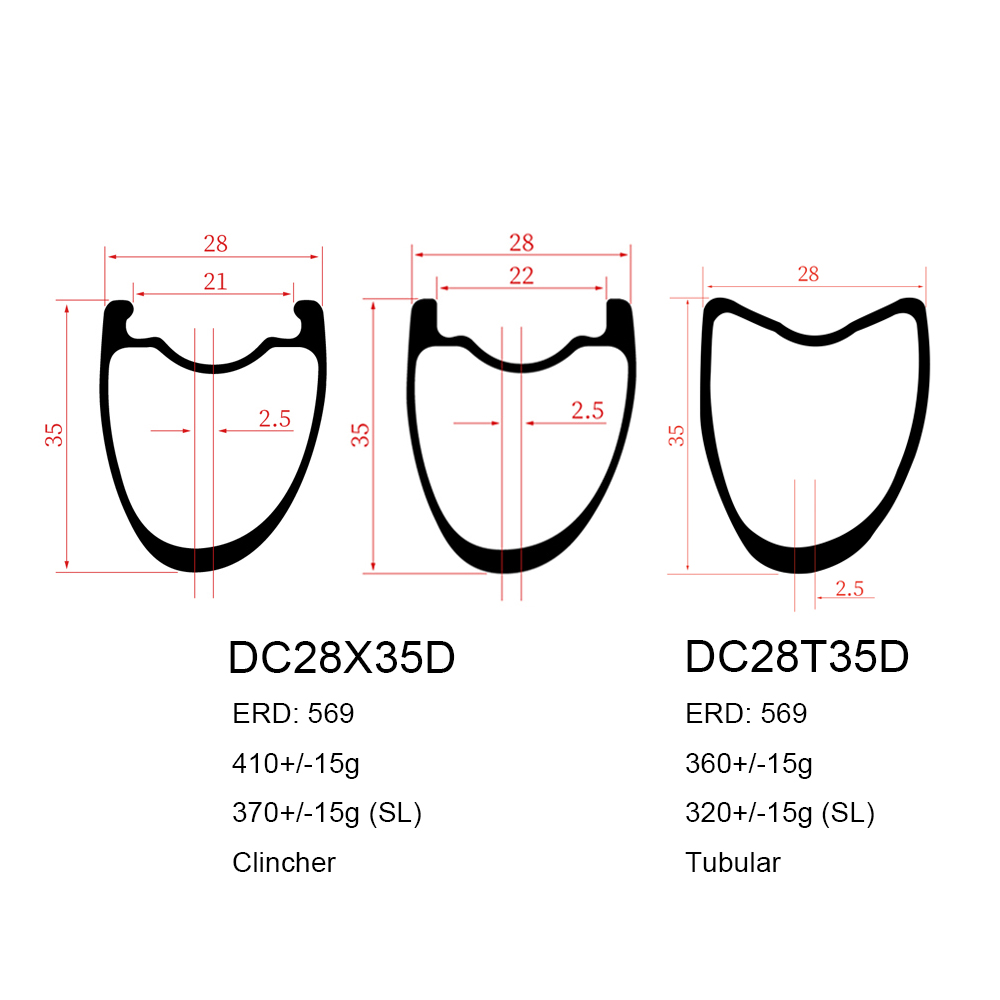

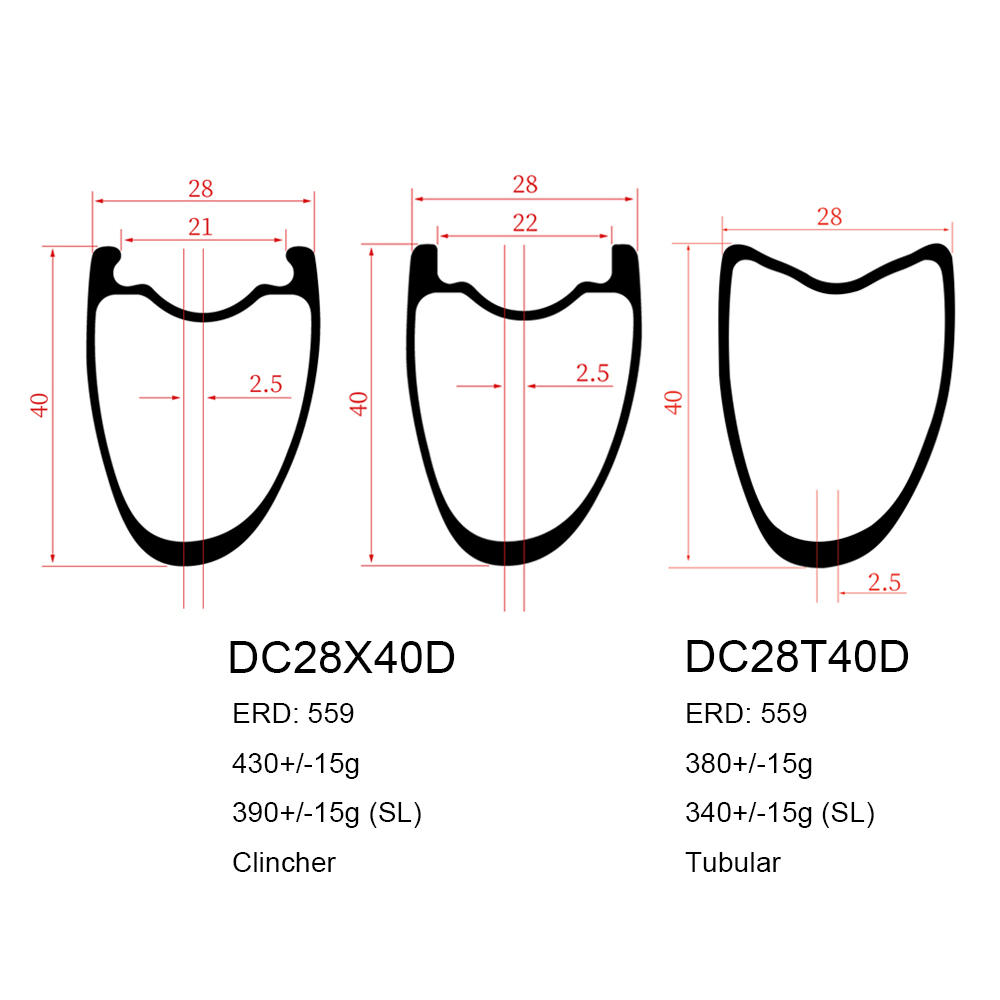

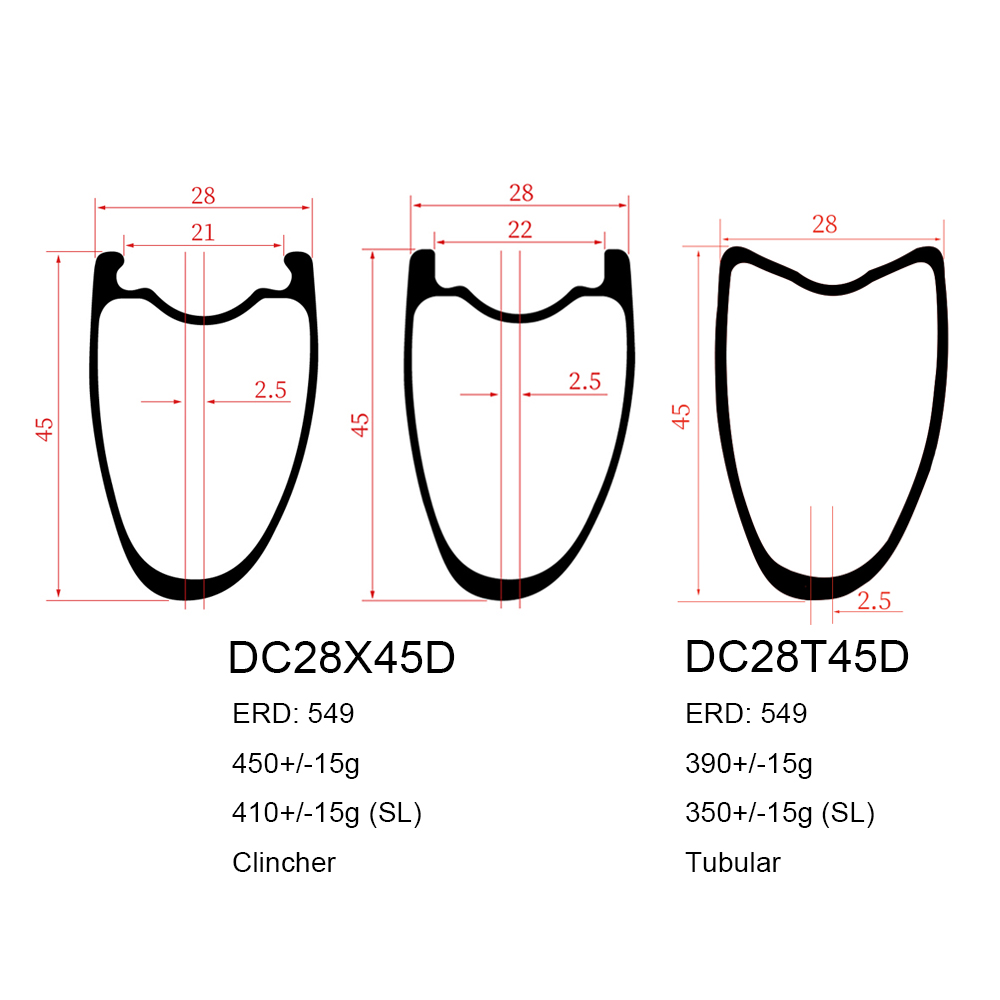

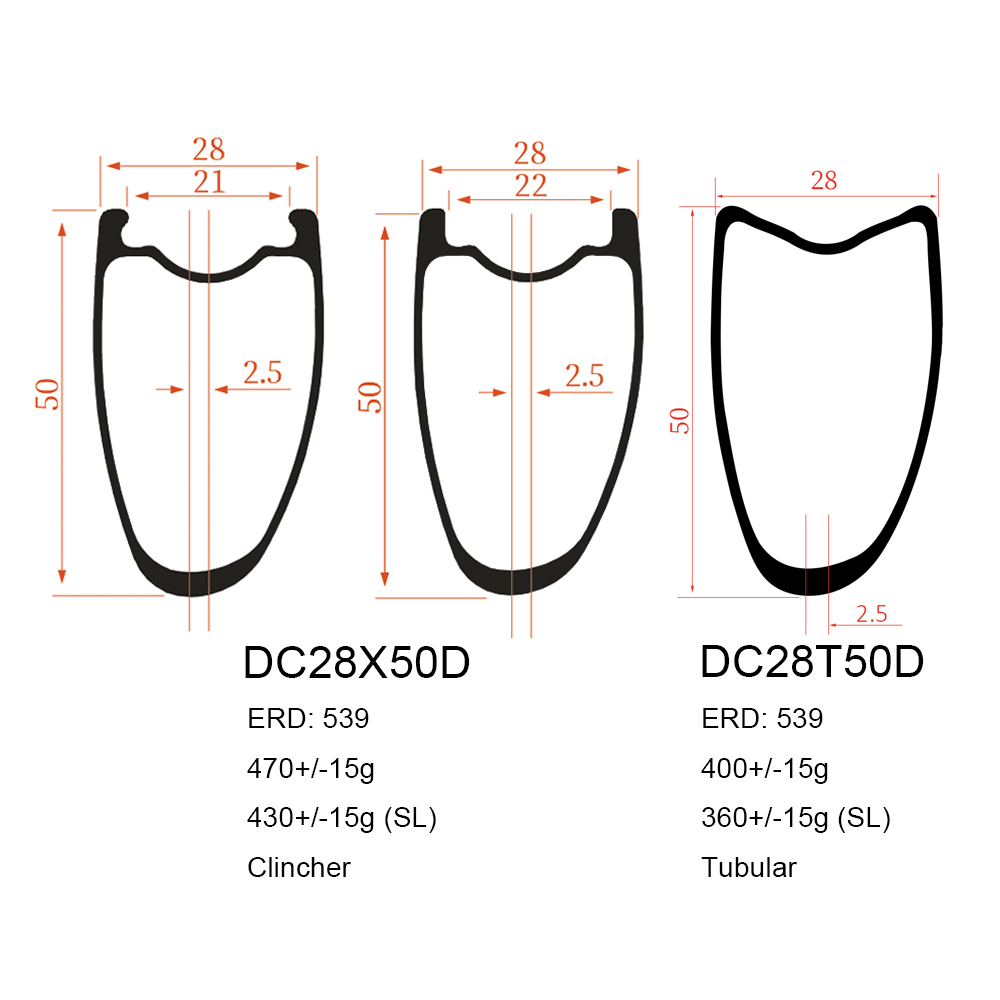

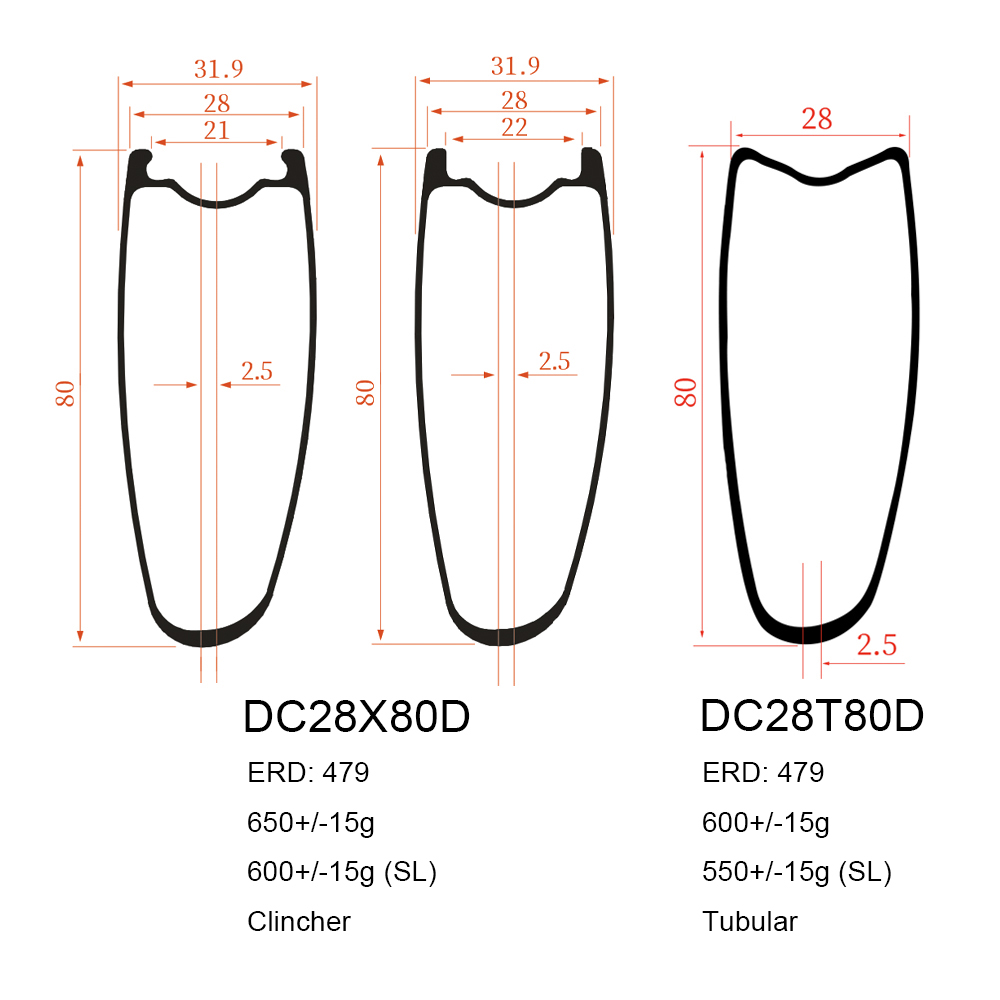

28mm Width Asymmetric- 丨35丨40丨45丨50丨80mm Depth - Tubeless Clincher/ Tubular

Carbon is the material of choice for high performance road/CX wheels. We’ve provided a wide range of carbon road/CX rims at unbeatable value. We make hookless and hook version for clincher models. Here is a peek at some of the technology shared with our road/CX rims.

BASIC TECHNOLOGIES

Tubeless Ready Technology

All of our clincher rims are tubeless compatible. The bead shape, bead seat and outer diameter is tailored according to each rim width to achieve the best fit. Tubeless (no tube) systems are designed to run at lower pressures than tube systems for a better grip and more comfortable ride. Eliminating the tube means there is no friction between tube and tire and therefore less rolling resistance when the tire rolls over the ground and obstacles.

Dynamic Speed Balance

In the quest to make lightern our rims, adding weights to achieve balance on our wheels is unacceptable. We use Dynamic Speed Balance (DSB™) on our rim layup design, a unique bicycle wheel balance system that doesn’t require added weights or gadgets to achieve perfect rotational wheel balance.The shaking reduces at least 90% compared to rims that don’t feature a wheel balance system.

Fast Tire Mounting

Our deeper tire bead channel provides easy tire mounting and dismounting. Most of our carbon rims are easy to install by tire lever, some of them even relatively easy to install only by hand.

Release Agent with Non-Contaminating Transfer

A release agent is applied on the mold to increase ease of rim removal. The most common release agent used in carbon rim manufacturing is oily and mixed with a small amount of wax. There will be some residue on the rim surface after it comes out of the mold, so wet-sanding is needed.

Finding an effective mold release agent that was also as green as possible proved to be challenging. We opted for release agent which is more expensive, and based on the product’s performance we stand by our decision. This release agent chemically bonds to the mold surface to form a micro thin film which is stable at temperatures exceeding most molding processes with non-contaminating transfer. After the molding process, the release agent flashes off so sanding is not required.

Natural UD Carbon Weave

To demonstrate the beauty of carbon weave, black paint is not added to cover the defect on rim surface. As a result, carbon fiber texture is clearly visible to the naked eye which brings a upscale look for the carbon rims.

Out From Mold as A Finished Product (Paintless/ No Painting)

Wet-sanding is not needed compared with traditional process, so the original epoxy resin layer is retained on the surface which results in higher strength and scratch resistance.

In addition, painting is not needed which is more environmentally friendly and contributes to a lighter rim.